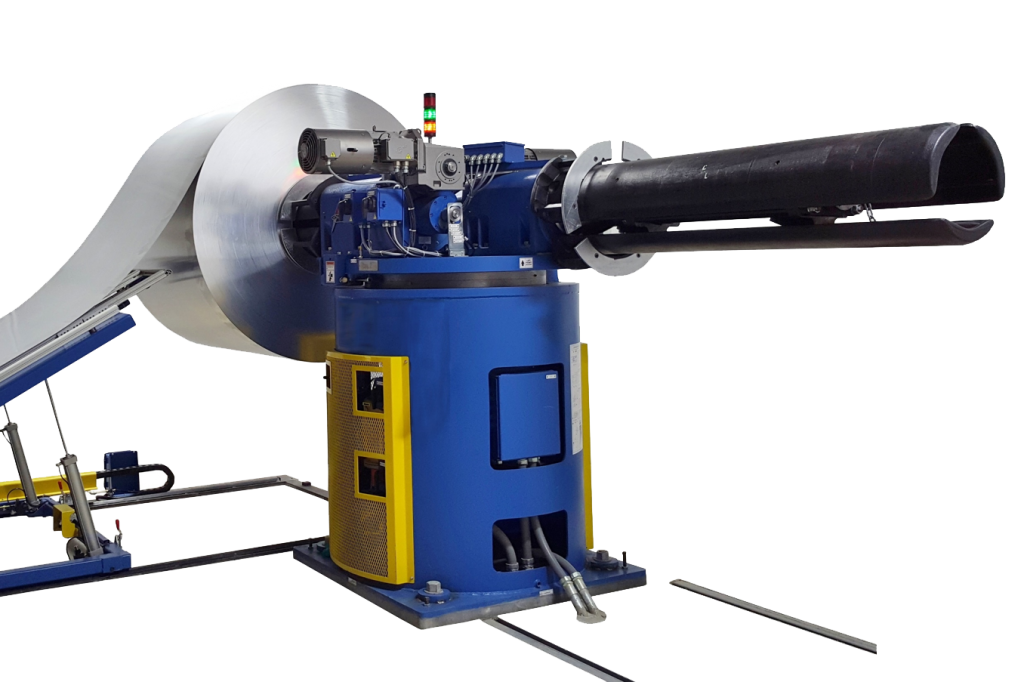

The 30,000-lb (13.608-kg), Double-Arm Uncoiler is a durable, electrically-controlled, self-contained, electric-powered machine for supporting and allowing payout of material stock from coils weighing up to 30,000-lb (13.608-kg) from one mandrel, while holding another in readiness.

The Double-Arm Uncoiler consists of two mandrel assemblies, each supported by two large tapered roller bearings mounted in a rugged, cast housing. The housings are bolted to a geardriven, rotating platform mounted onto a heavy, welded, steel base.

Each mandrel assembly is composed of three mandrel segments pinned to a central alloy-steel mandrel shaft. The segments are dovetail-mounted onto two cast wedges, which slide over the mandrel shaft. Expansion occurs when the wedges are pulled toward the uncoiler by a 6-in (152mm) bore, pull-rod cylinder which forces the segments outward. The segments collapse when the procedure is reversed. A pilot-operated check valve prevents accidental collapse of the mandrel.

The rotating platform, which provides the slewing (180°) feature of the unit, is mounted onto a 36-in (914mm) diameter slew ring bearing. A hydraulic motor and gear assembly intermeshes with the gear assembly on the ring to provide the slewing drive. A hydraulic-actuated locking pin is utilized to prevent the rotating platform from moving during payout operation.

Mandrel rotation is controlled by a smart loop control and electrical mandrel drive, which is supplied as standard equipment.

All hydraulic fluid to the slew motor and locking pin cylinder is provided by a central hydraulic power unit located inside the uncoiler base.