REDUCING STRESS ON CANS AND CANMAKERS.

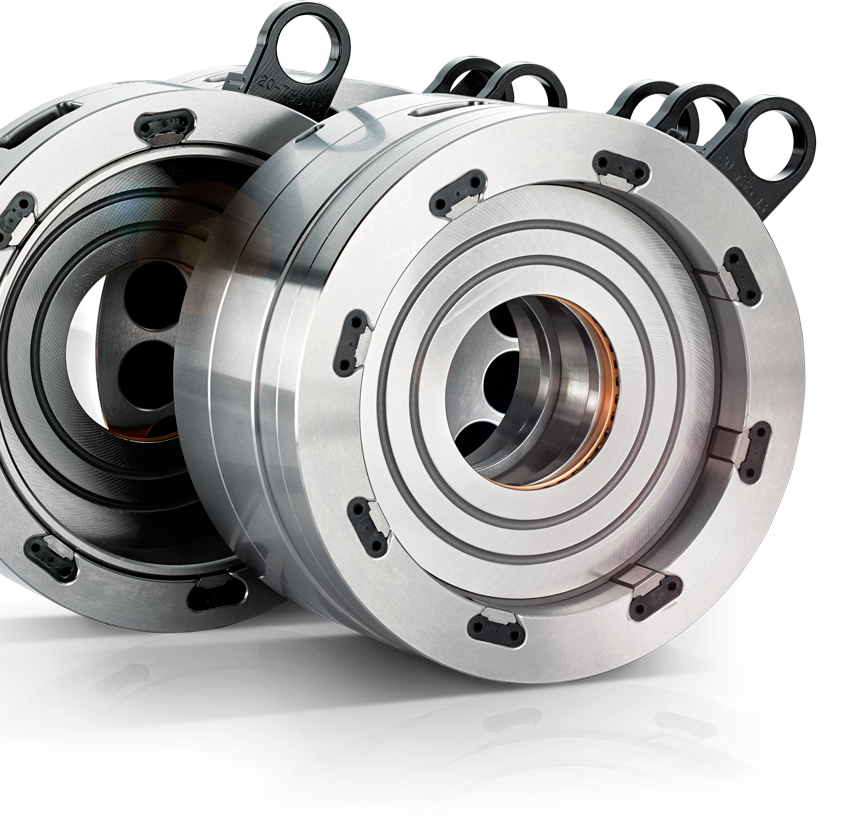

UNIQUE DIE SUSPENSION SYSTEM.

FEWER TEAROFFS.

A precision suspension system absorbs variation in ram position, putting less stress on the can. Precision locating pins return the die exactly to center–not past center. The closer the die is to center, the fewer tear offs you will experience.

THE CAN IS NOT A TOOL.

Fixed tool packs use the carbide die ring and the delicate can itself to force the punch back to center.

This stresses and wears the dies, but more alarmingly, puts incredible pressure on the can body. Stress you can really see in white streaks on steel cans where the tin ”re‐melts”.

Pride’s vibration dampening floating tool packs use a confined suspension system that never pushes the die past center and returns it to within 0.001” of perfect center before the next ram advance – design that delivers the best top wall concentricity with fewer tear offs. Other floating tool packs, such as o‐ring and quad‐ ring systems can’t center the die, and suffer from the same limitations of fixed tool packs resulting in increased die wear and poor can quality.

NEW PIN DESIGN. LONGER PIN LIFE.

Increased die contact area and extra hard pins help rings turn more easily and without outer diameter notching.

STRATEGIC OPENINGS.

SMARTER COOLING.

Most tool packs have single-spot cooling. Pride’s tactical openings throughout the tool pack increase can wall integrity and die life.

RESPECTED CANS ARE STRONGER CANS.

To reduce tearoffs can must be remove from the vibration equation and cooled more evenly and quickly.