Get smart with fluid application

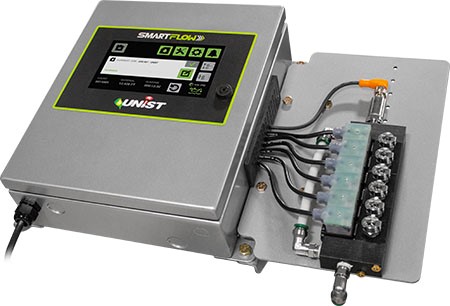

The SmartFlow® allows metal formers to take full control of die and stock lubrication. This full-featured, programmable fluid controller makes configuring, controlling, monitoring, and tracking fluid application easier than ever, leading to increased profits from the stamping or forming operation.

Designed around an intuitive and easy-to-use operator interface, the SmartFlow® provides simple and guided setup, advanced press control integration, fluid usage tracking, process monitoring, and enhanced diagnostic and maintenance tools.

Save and recall jobs manually or utilize the press control interface for easy, automatic changeover. Back up and transfer jobs and settings between lines with a USB flash drive and the SmartFlow’s® USB port. Pair the SmartFlow® controller with Unist’s proven line of precision fluid applicators for an intelligent lubrication system that eliminates wasted fluid and mess, reduces scrap, and maximizes profits.

The automatic lubrication system intermittently actuates a bank of fluid Solenoid Valves (up to 22 outputs) that dispense a programmed quantity of fluid to specific lube points. The valve actuation on this electronic fluid dispenser is determined by production line rates so there is no under or over lubrication whether it is a stamping press or roll forming operation.

SmartFlow® Benefits

- Monitors critical parameters

- Precision fluid control

- Controls up to 22 outputs

- Stores up to 250 different setups/jobs

- Access code prevents tampering

- Saves fluid: precisely controls fluid

Combine the SmartFlow® with a Uni-Roller® applicator to reduce fluid usage and save money

On average, a Unist automatic lubrication system can reduce stamping fluid consumption by 50% with some customers reporting reductions as high as 90%!

Touch screen interface – Easily access jobs, settings, maintenance reminders, and more. The intuitive menu allows for easy transition from box to production line

Process monitoring – The SmartFlow® controller can monitor pressure, flow, valve performance and line status to ensure lubrication is delivered as required

Easily create jobs – The job setup wizard guides users through creating a job. Once created, simply increase or decrease the amount of lubricant desired for quick fine tuning of lubricant coatings.

Fluid tracking – Take the guesswork out of tracking fluid consumption. Directly measure how much fluid your process is consuming with the optional flow meter. With the SmartFlow®, you’ll work smarter and know your exact lubricant cost per part